Electronics protection

Electrolube is a leading manufacturer of high-quality chemical products for the electronics industry. Mavom offers a wide range of specialized products from Electrolube that ensure the reliability and protection of electronic devices.

Potting resins

When potting electronics, components on a printed circuit board are completely isolated and well protected against environmental influences. Mavom's range of potting resins consists of silicones, polyurethanes, epoxies or hybrid products. There is a wide variety of viscosities, hardnesses and curing options. A number of products also meet certain standards such as EN 45545-2, UL or mil specs.

Conformal coatings

Applying a conformal coating, a specially developed thin layer of lacquer, is a relatively simple way to protect a printed circuit board against environmental influences. With a conformal coating, a selective area of the printed circuit board can be treated, repairs are easier to make and coverage is easy to check due to the presence of fluorescent substances in the lacquer.

Thermal Conductive Materials

Increased power on smaller surfaces as a result of product miniaturization provide extra heat development. Thermally conductive products dissipate heat efficiently, leading to better reliability and longer life of electronic components.

Also in our product range:

Cleaning

Cleaning is a crucial process in the production and use of electronics. Contact cleaners remove contamination and corrosion on electrical contacts, while other products dissolve flux residue after soldering. Proper cleaning of printed circuit boards ensures better adhesion when pouring, coating and bonding.

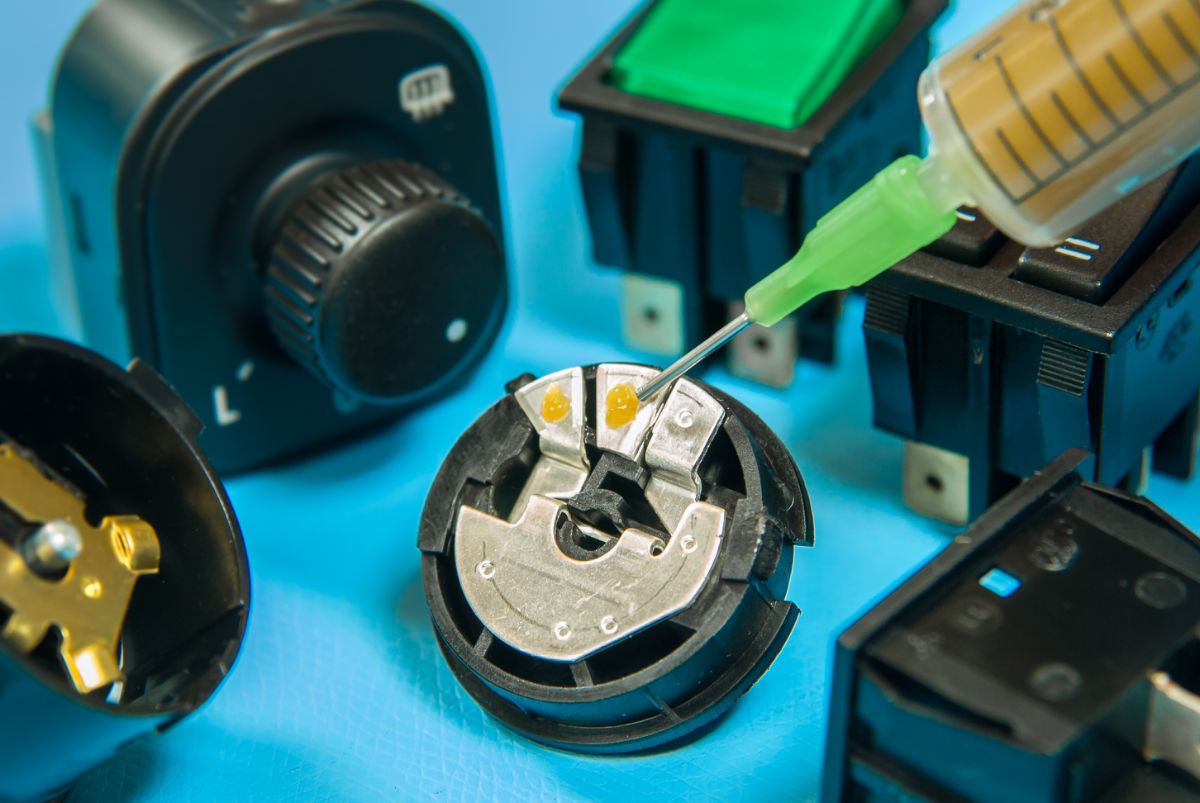

Contact lubricants

Contact lubricants are special greases and oils that reduce friction and wear, thereby improving the electrical performance of switches and connectors. Tests have shown that contact lubricants extend the life of switches by 300%. They also prevent the ingress of moisture, so that no corrosion occurs.

Electrolube

The origins of Electrolube can be traced back to 1941 when the development of a volume regulator demanded a special oil to reduce the friction of moving parts. This was the basis for a range of contact lubricants. Since then, Electrolube has grown into a worldwide specialist in chemical products for the electronics industry, including potting resins, conformal coatings, thermally conductive products and cleaning solutions.

Nederland - Nederlands

Nederland - Nederlands België - Nederlands

België - Nederlands Deutschland - Deutsch

Deutschland - Deutsch